Large Floor Type Lathe Series are mainly used for turning not only the end face, ex-circle surface, but also the conical surface of various work-pieces. This machine adopts three supporting structure with good rigidity. Designing flexible lateral chip removal system with good performance. This machine is equipped with separate oil pump with excellent lubrication. The tailstock movement adopts mechanical device with reasonable rotation speed, feed rate and power. This kind of lathe has high rigidity, efficiency, energy-saving, easy operation and attractive appearance.

CW series Large floor type Lathe Machines designed by my company adopts new-designed and optimized headstock, which utilizes 3D motion simulation to make the spindle box runs more stable. And this design shifts the gears more smoother. And expand the rotation speed range.

Secondly, integration of automatic feed system. This lathe is installed variable frequency converter and servo motor to improve the automatic level of the machine. Meanwhile, it improves the machine accuracy also and reduce the malfunction of the lathe. Besides, it greatly improves the safety and convenience of the lathe machine.

The machine has the advantages of large bearing capacity, strong rigid, beautiful appearance and convenient operation. It is mainlay used for turning the internal and external cylindrical surface, end face, circular arc and other shaped surfaces of various parts like tyre mold, disc parts, flange, valves, pressure vessel,mining equipment and so on.

TEl£º086-0532-83205888 Fax£º086-0532-83205777

TEl£º086-0532-83205888 Fax£º086-0532-83205777

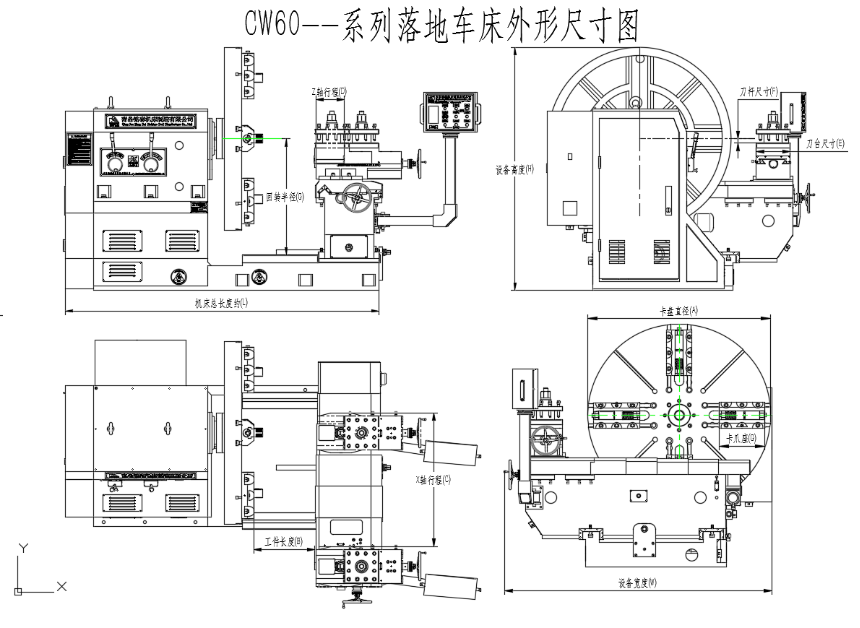

Specifications Table of CW60 series Standard Large Horizontal Lathe

|

Name/Type |

Unit/Symbol |

CW6016 |

CW6018 |

CW6020 |

CW6025 |

CW6030 |

|

|

|

|

Basic Datas |

|

|

|

|

Manuturing Brand |

|

Mingtai |

Mingtai |

Mingtai |

Mingtai |

Mingtai |

|

Swing Diameter over machine bed( G*2) |

mm |

¦Õ1600mm |

¦Õ1800mm |

¦Õ2000mm |

¦Õ2500mm |

¦Õ3000mm |

|

Chuck Diameter A |

mm |

¦Õ1250mm |

¦Õ14000mm |

¦Õ1600m |

¦Õ2000mm |

¦Õ2500mm |

|

Length of Chuck Jaw Seat G |

mm |

400mm |

400mm |

500m |

500mm |

500mm |

|

Max.Work-piece Length B |

mm |

500mm |

500mm |

500mm |

750mm |

1000mm |

|

Load Bearing Capacity |

T |

2T |

2T |

3T |

3T |

3T |

|

Spindle Diameter |

mm |

190mm |

190mm |

190mm |

220mm |

260mm |

|

Spindle Diameter |

gear shifts |

6 gear shifts |

6 gear shifts |

6 gear shifts |

3 gear shifts |

3 gear shifts |

|

Spindle Speeds |

r/min |

14~108r/min |

14~108r/min |

13~86r/min |

4~106r/min |

4~106r/min |

|

X Axis Stroke (C) |

mm |

800mm |

900mm |

1000mm |

1250mm |

1500mm |

|

Z Axis Stroke (D) |

mm |

350mm |

350mm |

350mm |

350mm |

350mm |

|

Rapid Feed of X Axis |

mm/min |

2500mm/min |

2500mm/min |

2500mm/min |

2500mm/min |

2500mm/min |

|

Rapid Feed of Z Axis |

mm/min |

2000mm/min |

2000mm/min |

2000mm/min |

2000mm/min |

2000mm/min |

|

Size of Electrical Cutting Tool Carriage (E) |

mm |

300*300mm |

300*300mm |

300*300mm |

300*300mm |

300*300mm |

|

Cutting Tool Holder Size (F) |

mm |

40*40mm |

40*40mm |

40*40mm |

0*40mm4 |

40*40mm |

|

Feed Numbers |

gear shifts |

20 gear shifts |

20 gear shifts |

20 gear shifts |

20 gear shifts |

20 gear shifts |

|

|

|

|

Motor Data |

|

|

|

|

Main motor power |

KW |

11KW |

11KW |

15KW |

18.5KW |

22KW |

|

Feed Motor Power |

KW |

2.3KW |

2.3KW |

2.3KW |

2.3KW |

2.3KW |

|

Lubrication Motor Power |

KW |

0.37KW |

0.37KW |

0.37KW |

0.55KW |

0.55KW |

|

|

|

|

Machine Accuracy Data |

|

|

|

|

Cylindricity of Machine |

mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

|

Cylindricity of Machine |

mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

|

|

| |||||

|

Machine Roughness |

Ra |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

|

Machine Dimensions L*W*H |

mm |

About 2800*1850*1800mm |

About 2800*1950*1900mm |

About 2800*2000*2000mm |

About 3250*2650*2650mm |

About 3500*3300*3200mm |

|

Machine Weight |

T |

About 6T |

About 6.5T |

About 8T |

About 12.5T |

About 15T |

CW6050

CW6030

CW6025

CW6020

Wechat Contact

National Serving Advisory Hotline

0532-83205888