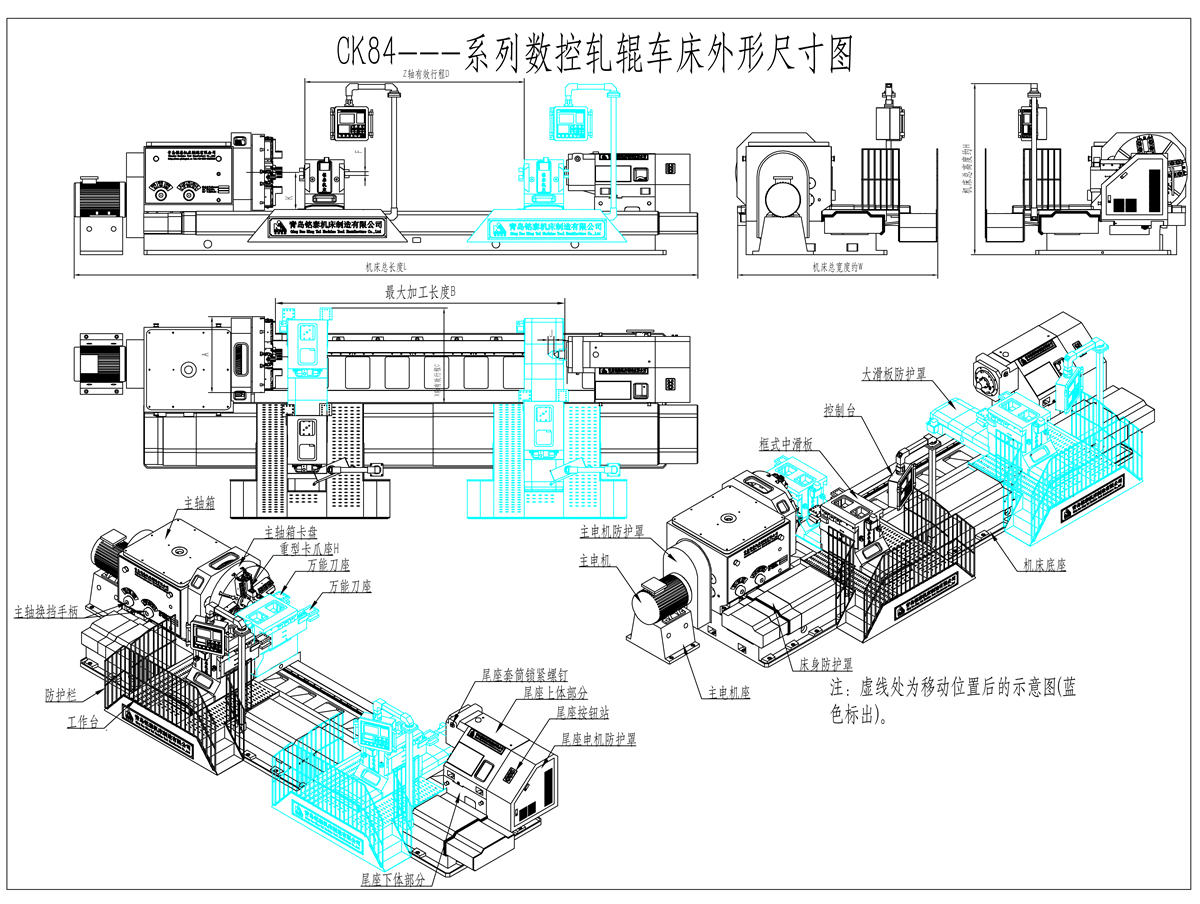

Roll Turning CNC Lathe series are mainly used for turning not only the end face, ex-circle surface, but also the conical surface of various work-pieces. This machine adopts three supporting structure with good rigidity. Designing flexible lateral chip removal system with good performance. This machine is equipped with separate oil pump with excellent lubrication. The tailstock movement adopts mechanical device with reasonable rotation speed, feed rate and power. This kind of lathe has high rigidity, efficiency, energy-saving, easy operation and attractive appearance.

CK84 series Horizontal Roll Turning CNC Lathe Machines designed by my company adopts new-designed and optimized headstock, which utilizes 3D motion simulation to make the spindle box runs more stable. And this design shifts the gears more smoother. And expand the rotation speed range.

Secondly, integration of automatic feed system. This lathe is installed variable frequency converter and servo motor to improve the automatic level of the machine. Meanwhile, it improves the machine accuracy also and reduce the malfunction of the lathe. Besides, it greatly improves the safety and convenience of the lathe machine.

The machine has the advantages of large bearing capacity, strong rigid, beautiful appearance and convenient operation. It is mainlay used for turning the internal and external cylindrical surface, end face, circular arc ,etc. It is the best professional lathe machine for turning steel rolls.

TEl£º086-0532-83205888 Fax£º086-0532-83205777

TEl£º086-0532-83205888 Fax£º086-0532-83205777

Specifications Table of CK84 series Heavy Duty Roll Turning Lathe with PLC

|

Name/Type |

Unit/Symbol |

CK8465 |

CK8480 |

CK84100 |

CK84125 |

CK84160 |

CK84200 |

|

|

|

|

|

Basic Datas |

|

|

|

|

Manuturing Brand |

|

Mingtai |

Mingtai |

Mingtai |

Mingtai |

Mingtai |

Mingtai |

|

Guide Rail Type of Machine Bed |

|

Three Guide Rails with Rectangle Type. |

Three Guide Rails with Rectangle Type. |

Three Guide Rails with Rectangle Type. |

Three Guide Rails with Rectangle Type. |

Three Guide Rails with Rectangle Type. |

Three Guide Rails with Rectangle Type. |

|

Machining Diameter of Work-piece K*2 |

mm |

¦Õ650mm |

¦Õ800mm |

¦Õ1000mm |

¦Õ1250mm |

¦Õ1600mm |

¦Õ2000mm |

|

Guide Rail Width |

mm |

1000mm |

1100mm |

1400mm |

1600mm |

1800mm |

2000mm |

|

Chuck Diameter A |

mm |

¦Õ630mm 4 jaws Independent Chuck |

¦Õ800mm 4 jaws Independent Chuck |

¦Õ1000 4 jaws Independent Chuck |

¦Õ1250mm 4 jaws Independent Chuck |

¦Õ1600mm 4 jaws Independent Chuck |

¦Õ2000mm 4 jaws Independent Chuck |

|

Length of Chuck Jaw Seat (H) |

mm |

250mm heavy duty chuck jaw seat |

250mm heavy duty chuck jaw seat |

320mm heavy duty chuck jaw seat |

320mm heavy duty chuck jaw seat |

320mm heavy duty chuck jaw seat |

320mm heavy duty chuck jaw seat |

|

Max.Work-piece Length (B) |

mm |

4000mm |

5000mm |

8000mm |

12000mm |

15000mm |

20000mm |

|

Load Bearing Capacity |

T |

10T |

18T |

25T |

32T |

40T |

50T |

|

Spindle Diameter |

mm |

¦Õ190mm |

¦Õ220mm |

¦Õ260mm |

¦Õ300mm |

¦Õ300mm |

¦Õ360mm |

|

Gear Shifts of Spindle |

gear shifts |

3 gear shifts |

3 gear shifts |

3 gear shifts |

3 gear shifts |

3 gear shifts |

6 gear shifts |

|

Spindle Speeds |

r/min |

5~260r/min |

2~165r/min |

2~130r/min |

2~130r/min |

2~80r/min |

0.5~80r/min |

|

Tips Specifications of Spindle |

|

Metric 80 1:7 |

Metric 80 1:7 |

Metric 100 1:7 |

Metric 120 1:7 |

Metric 120 1:7 |

Metric 160 1:7 |

|

X Axis Stroke (C) |

mm |

50-325mm |

50-400mm |

50-500mm |

100-625mm |

100-800mm |

200-1000mm |

|

Z Axis Stroke (D) |

mm |

1000-4000mm |

1000-5000mm |

2000-8000mm |

2000-12000mm |

3000-15000mm |

3000-20000mm |

|

Rapid Feed of X Axis |

mm/min |

2000mm/min |

2000mm/min |

2000mm/min |

2500mm/min |

2500mm/min |

2500mm/min |

|

Rapid Feed of Z Axis |

mm/min |

2500mm/min |

2500mm/min |

2500mm/min |

2500mm/min |

2500mm/min |

3000mm/min |

|

Cutting Tool Carriage Type |

|

Square-type Cutting Tool Plate |

Square-type Cutting Tool Plate |

Square-type Cutting Tool Plate |

Square-type Cutting Tool Plate |

Square-type Cutting Tool Plate |

Square-type Cutting Tool Plate |

|

Pressure Cutter Size |

mm |

40*40mm |

40*40mm |

50*50mm |

50*50mm |

70*70mm |

70*70mm |

|

Tailstock Spindle Diameter |

mm |

¦Õ240mm |

¦Õ290mm |

¦Õ290mm |

¦Õ320mm |

¦Õ320mm |

¦Õ410mm |

|

Tailstock Sleeve Stroke(J) |

mm |

300mm |

300mm |

300mm |

300mm |

300mm |

300mm |

|

Tailstock Movement Method |

|

Electrical Control |

Electrical Control |

Electrical Control |

Electrical Control |

Electrical Control |

Electrical Control |

|

Specifications of Tailstock Tips |

|

Metric 80 1:7 |

Metric 80 1:7 |

Metric 100 1:7 |

Metric 120 1:7 |

Metric 120 1:7 |

Metric 160 1:7 |

|

Max.Cutting Force of Single Cutting Tool Holder |

KN |

40KN |

50KN |

50KN |

80KN |

100KN |

150KN |

|

Max.Cutting Force of Chuck |

KN/m |

13KN/m |

22KN/m |

33KN/m |

40KN/m |

90KN/m |

233KN/m |

|

Total Cutting Force |

KN |

45KN |

60KN |

70KN |

110KN |

160KN |

210KN |

|

CNC Control System |

|

SIEMENS 828 D System |

SIEMENS 828 D System |

SIEMENS 828 D System |

SIEMENS 828 D System |

SIEMENS 828 D System |

SIEMENS 828 D System |

|

|

|

|

|

Motor Data |

|

|

|

|

Main motor power (DC) |

KW |

22KW(According to the Work-piece with 3000 mm length) |

37KW(According to the Work-piece with 3000 mm length) |

45KW(According to the Work-piece with 3000 mm length) |

55KW(According to the Work-piece with 5000 mm length) |

75KW(According to the Work-piece with 7000 mm length) |

128KW(According to the Work-piece with 8000 mm length) |

|

Lubrication Motor Power |

KW |

0.37KW |

0.37KW |

0.55KW |

0.55KW |

0.55KW |

0.55KW |

|

|

|

|

|

Machine Accuracy Data |

|

|

|

|

Cylindricity of Machine |

mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

|

Machine Flatness |

mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

0.03/300mm |

|

Machine Roughness |

Ra |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

Ra3.2 |

|

Machine DimensionsL*W*H |

mm |

About 6000*2000*1400mm |

About 7500*2200*1650mm |

About 8100*2750*1950mm |

About 10000*3100*2150mm |

About 10500*3200*2400mm |

About 12500*3600*2650mm |

|

Machine Weight |

T |

About 20T(3m) |

About 23T(3m) |

About 26T(3m) |

About 35T(5m) |

About 46T(7m) |

About 65T(8m) |

CK84200

CK84160

CK84100

CK8465

Wechat Contact

National Serving Advisory Hotline

0532-83205888